OSW FIRE

in the performance levels L1, L2 and L3

Advantages

- very low weight to relieve fire fighting forces

- very good kink radius for high flexibility

- low friction/pressure loss due to smooth EPDM-rubberlining

- high-quality EPDM-rubberlining is extremly resistant to aging, ozone and UV radiation

- root resistant, low maintenance

- cold resistance: up to – 40 °C

- heat resistance: up to + 100 °C (for water)

- signal colors offer high perceptibility/visibility in buildings and difficult terrain

- also suitable for sea water, hot water, water steam and many other chemicals

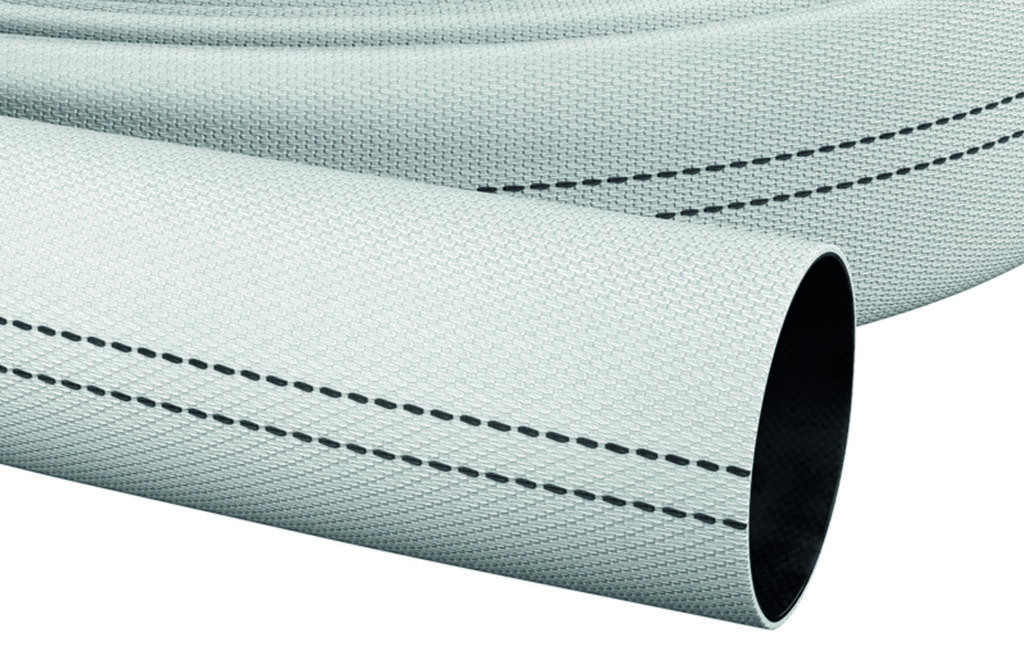

Hose construction

-

Inside: high-quality, very light synthetic rubber on the basis of EPDM

-

Outside: jacket of 100 % high tenacity synthetic polyester yarn, circular-woven twill weave, warp and weft threads multiple twisteds, available in various fabric constructions of performance levels L1 to L3

Colours

![]()

Applicable Standards

- according to DIN14811:2008-01, DIN14811/A1:2012-03, DIN14811/A2:2014-08 + DIN14811/A3:2018-11 class 1

- according to BS 6391:2009 Type 1

- ÖNORM F2105

Approval or test certificates will send on request.

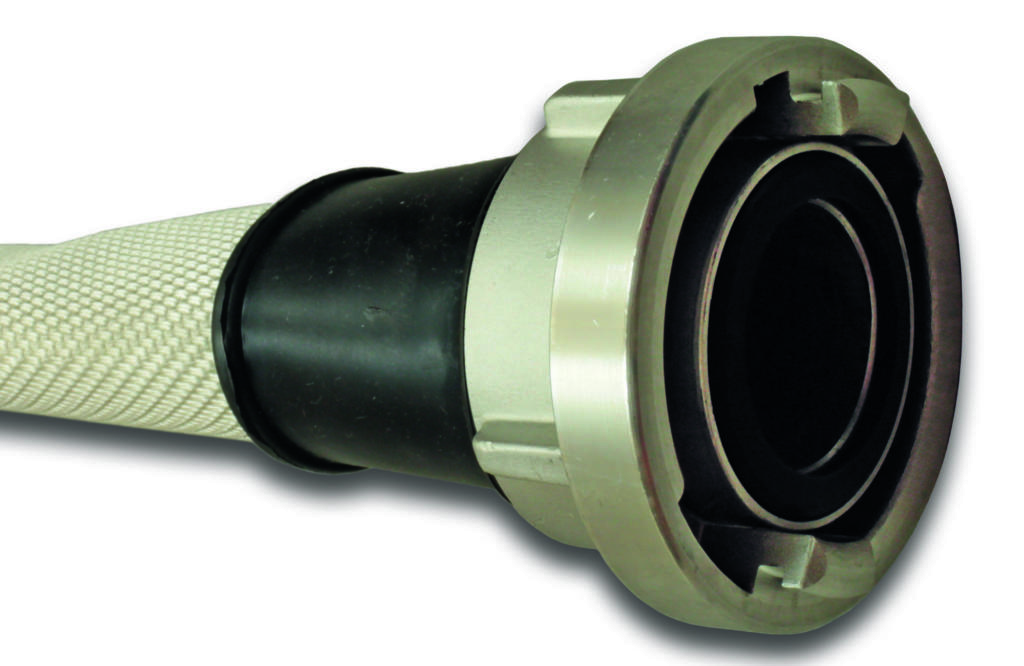

Service

- individual printing possible (e.g. company logo) – hose can be connected with national and international couplings

- binding: wire, smartFIT, clamps, Iconos, Innotrade, press sleeves etc.

- impact and abrasion cuffs over the binding (smooth or conical)

- repair or sliding sleeves in different designs

- innovations: smartFIT, smartPROTECT, RFID chip, edge gliders

- on customer request: double rolled, untwisted, with factory test report

Performance levels

The fire hose OSW FIRE is available in diameters of 42 mm and 52 mm (C-hose) as well as 75 mm (B-hose) in the performance levels L1, L2 and L3. The higher the performance level, the higher the abrasion resistance of the fire hose.

OSW FIRE L1

Fabric Construction

warp 3-ply twisted

-> without identification stripes

Colours

Version

without „Protect“ impact and abrasion protection

over the binding (smooth or conical) –

optionally possible

OSW FIRE L2

Fabric Construction

warp 3-ply twisted (reinforced)

-> with 2 black identification stripes

Colours

Version

with „Protect“ impact and abrasion protection

over the binding (smooth or conical)

Technical Details

The data regarding bursting pressure and working pressure refer only to the pure hose without couplings. Changes in technical specification without prior notice.

| Diameter Inch | Diameter mm | Bursting pressure (in fact) bar | Bursting pressure (DIN) bar | Working pressure (DIN) bar | Bending Radius (DIN) mm | Volume Flow Rate L /min | Theo. Tensile Strength kg | Wall Thickness mm | Weight (+/– 5 %) g/m | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 25 | 90 | 60 | 16 | 250 | 140 | 2.300 | 1.5 | 130 | X | X | X | X | |

| 1 1/4 | 32 | 90 | 60 | 16 | 320 | 140 | 2.600 | 1.5 | 165 | X | ||||

| 1 1/2 | 38 | 85 | 60 | 16 | 380 | 500 | 3.200 | 1.65 | 190 | X | X | |||

| 1 2/3 | 42 | L1 | 70 | 60 | 16 | 420 | 600 | 4.200 | 1,65 | 240 | X | X | X | X |

| 1 2/3 | 42 | L2 | 72 | 60 | 16 | 420 | 600 | 5.200 | 1,65 | 250 | X | X | X | X |

| 1 2/3 | 42 | L3 | 74 | 60 | 16 | 420 | 600 | 6.200 | 1,65 | 260 | X | X | X | X |

| 1 3/4 | 45 | 70 | 60 | 16 | 450 | 800 | 3.800 | 1.65 | 245 | X | ||||

| 2 | 52 | L1 | 75 | 60 | 16 | 520 | 1.200 | 5.800 | 1,65 | 290 | X | X | X | X |

| 2 | 52 | L2 | 77 | 60 | 16 | 520 | 1.200 | 6.600 | 1,65 | 305 | X | X | X | X |

| 2 | 52 | L3 | 80 | 60 | 16 | 520 | 1.200 | 7.700 | 1,65 | 320 | X | X | X | X |

| 2 1/6 | 55 | 73 | 60 | 16 | 550 | 1.200 | 4.600 | 1.65 | 315 | X | X | |||

| 2 1/2 | 64 | 73 | 60 | 16 | 640 | 1.800 | 5.700 | 1.75 | 385 | X | ||||

| 2 1/2 | 65 | 73 | 60 | 16 | 650 | 1.800 | 5.700 | 1.75 | 385 | X | ||||

| 2 1/2 | 66 | 73 | 60 | 16 | 660 | 1.800 | 5.700 | 1.75 | 385 | X | ||||

| 2 3/4 | 70 | 69 | 60 | 16 | 700 | 1.800 | 6.800 | 1.75 | 425 | X | X | |||

| 3 | 75 | L1 | 67 | 60 | 16 | 750 | 2.400 | 8.600 | 1,75 | 475 | X | X | X | X |

| 3 | 75 | L2 | 69 | 60 | 16 | 750 | 2.400 | 10.200 | 1,75 | 500 | X | X | X | X |

| 3 | 75 | L3 | 71 | 60 | 16 | 750 | 2.400 | 10.200 | 1,75 | 525 | X | X | X | X |

| 3 1/2 | 90 | 55 | 35 | 12 | 900 | 3.500 | 9.100 | 1.95 | 580 | X | ||||

| 4 | 102 | 50 | 35 | 12 | 1.020 | 4.700 | 9.500 | 1.95 | 660 | X | ||||

| 4 1/3 | 110 | 50 | 35 | 12 | 1.100 | 5.200 | 11.700 | 1.95 | 780 | X | X | X | ||

| 5 | 125 | 45 | 35 | 12 | 1.250 | 7.000 | 12.800 | 2.1 | 870 | X | ||||

| 6 | 150 | 42 | 35 | 12 | 1.500 | 10.000 | 12.800 | 2.1 | 950 | X | ||||

| 8 | 205 | 35 | 30 | 10 | 2.050 | 20.000 | 24.500 | 2.1 | 1.075 | X |

Production

Pictures, videos and descriptions from the production

Media

Galleries, videos and PDF

Glossary

Alphabetically arranged subject index, multilingual