OSW FIRE SAFETY

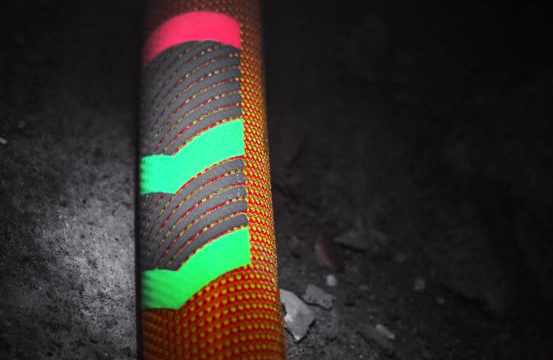

Fire Hose

Special features

- Luminous directional arrows along the entire length of the tube show you the way out

- Reflective function and glow-in-the-dark effect in ‘traffic light’ symbolism (reflective and photoluminescent component)

- Equipped with SmartPROTECT cuffs on both sides, which can optionally be fitted with an RFID chip

- Connect the red cuff to the nozzle, the green cuff to the outlet

- Modified design makes it flexible and flat, making it ideal for indoor use (hose package/carrying cage)

Advantages

- very low weight to relieve fire fighting forces

- very good kink radius for high flexibility

- low friction/pressure loss due to smooth EPDMrubberlining

- high-quality EPDM-rubberlining is extremly resistant to aging, ozone and UV radiation

- root resistant, low maintenance

- cold resistance: up to – 40 °C

- heat resistance: up to + 100 °C (for water)

- signal color and directional arrow offer high recognition/ visibility in buildings and in the area

- also suitable for sea water, hot water, water steam and many other chemicals

Hose construction

-

Inside: high-quality, very light synthetic rubber on the basis of EPDM

-

Outside: jacket of 100 % high tenacity synthetic polyester yarn, circular-woven twill weave, warp and weft threads multiple twisteds

Colours

Service

- individual printing possible (e.g. company logo)

- hose can be connected with national and international couplings

- binding: wire, smartFIT, clamps, Iconos, Innotrade, press sleeves etc.

- impact and abrasion cuffs over the binding (smooth or conical)

- repair or sliding sleeves in different designs

- innovations: smartFIT, smartPROTECT, RFID chip, directional arrow, edge gliders

- on customer request: double rolled, untwisted, with factory test report

Product Video

Technical Details

The data regarding bursting pressure and working pressure refer only to the pure hose without couplings. Changes in technical specification without prior notice.

| Diameter Inch | Diameter mm | Bursting pressure (in fact) bar | Bursting pressure (DIN) bar | Working pressure (DIN) bar | Bending radius (DIN) mm | Volume Flow Rate L/min | Theo. Tensile Strength kg | Wall Thickness mm | Weight (+/- 5%) g/m |

|---|---|---|---|---|---|---|---|---|---|

| 1 2/3 | 42 | 75 | 60 | 16 | 420 | 600 | 6.200 | 1,65 | 240 |

Production

Pictures, videos and descriptions from the production

Media

Galleries, videos and PDF

Glossary

Alphabetically arranged subject index, multilingual