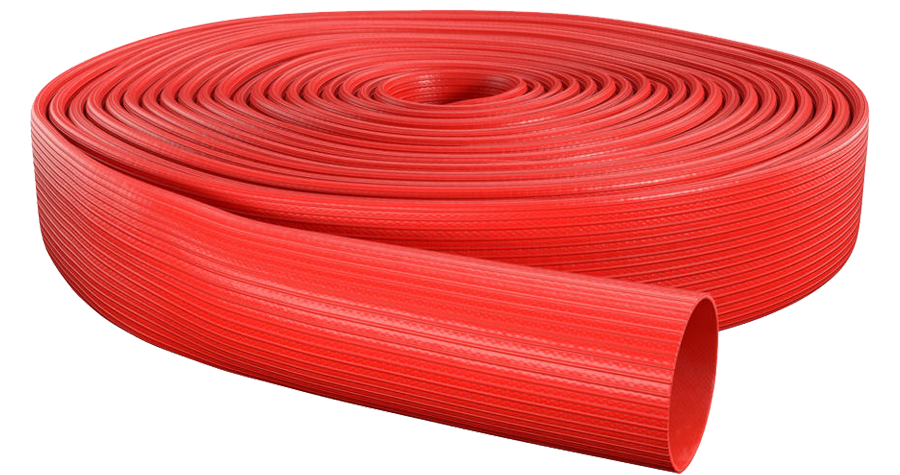

OSW UNIDUR

Inside and Outside Rubberlined Fire Fighting Hose

Advantages

- high abrasion resistance and durability by longitudinal ribs

- by trouble with a damage of the cover an easily repair is possible

- very good kink radius for high flexibility

- low friction/pressure loss due to very smooth inside rubberlined

- high-quality Nitrile/PVC-rubberlining is extremly resistant to aging, ozone and UV radiation

- root resistant, low maintenance

- cold resistance: up to – 40 °C

- heat resistance: up to + 100 °C (for water)

- also suitable for sea water, hot water, water steam and many other chemicals

Hose Construction

-

Inside: very smooth high-quality Nitrile/PVC rubberlining, jacket of 100 % high tenacity synthetic polyester yarn, circular-woven twill weave, warp and weft threads multiple twisted, embedded in a rubber compound, optimum protection of the jacket

-

Outside: high-quality Nitrile/PVC rubberlining with longitudinal ribs

Colours

Applicable Standards

- according to DIN14811:2008 class 3

- according to BS 6391:2009 Type 3

- with Lloyd’s Register approval

Approval or test certificates will send on request.

Service

- individual printing possible (e.g. company logo)

- can be connected with national and international couplings

- binding: wire, smartFIT, clamps, Iconos, Innotrade, press sleeves etc.

- impact and abrasion cuffs over the binding (smooth or conical)

- repair or sliding sleeves in different designs

- innovations: smartFIT, smartPROTECT, RFID chip, edge gliders

- on customer request: double rolled, untwisted, with factory test report

Technical Details

The data regarding bursting pressure and working pressure refer only to the pure hose without couplings. Changes in technical specification without prior notice.

| Diameter Inch | Diameter mm | Bursting Pressure (in fact) bar | Bursting Pressure (DIN) bar | Working Pressure (DIN) bar | Bending Radius (DIN) mm | Volume Flow Rate L/min | Theo. Tensile Strength kg | Wall Thickness mm | Weight (+/- 5%) g/m |

|---|---|---|---|---|---|---|---|---|---|

| 3/4 | 19 | 75 | 50 | 16 | 190 | 140 | 1.800 | 2,20 | 195 |

| 1 | 25 / 27 | 75 | 50 | 16 | 250 / 270 | 140 | 2.300 | 2,00 | 220 |

| 1 1/4 | 32 | 65 | 50 | 16 | 320 | 500 | 2.700 | 2,00 | 270 |

| 1 1/2 | 38 | 65 | 50 | 16 | 380 | 500 | 3.100 | 2,20 | 315 |

| 1 2/3 | 42 | 65 | 50 | 16 | 420 | 600 | 3.100 | 2,00 | 340 |

| 1 3/4 | 45 | 65 | 50 | 16 | 450 | 800 | 3.300 | 2,00 | 350 |

| 2 | 52 | 60 | 50 | 16 | 520 | 1.200 | 3.900 | 2,30 | 400 |

| 2 1/2 | 64 / 65 / 66 | 60 | 50 | 16 | 640 / 650 / 660 | 1.800 | 5.200 | 2,30 | 575 |

| 2 3/4 | 70 | 60 | 50 | 16 | 700 | 1.800 | 5.800 | 2,30 | 620 |

| 3 | 75 | 60 | 50 | 16 | 750 | 2.400 | 7.000 | 2,50 | 740 |

| 3 1/2 | 90 | 50 | 35 | 12 | 900 | 3.500 | 7.900 | 2,80 | 860 |

| 4 | 102 | 45 | 35 | 12 | 1.020 | 4.700 | 8.200 | 2,50 | 1.140 |

| 4 1/3 | 110 | 45 | 35 | 12 | 1.100 | 5.200 | 8.800 | 2,90 | 1.140 |

| 5 | 125 | 45 | 35 | 12 | 1.250 | 7.000 | 12.500 | 3,00 | 1.260 |

| 6 | 150 | 38 | 35 | 12 | 1.500 | 10.000 | 13.300 | 3,00 | 1.700 |

| 8 | 203 | 35 | 30 | 10 | 2.030 | 20.000 | 23.400 | 3,50 | 3.000 |

| 10 | 254 | on request | on request | on request | on request | on request | on request | on request | on request |

Production

Pictures, videos and descriptions from the production

Media

Galleries, videos and PDF

Glossary

Alphabetically arranged subject index, multilingual