OSW smartTAG

The ‘smart’ hose patch.

Advantages

-

Contactless data transmission between reader and transponder

-

Enables simple and digital identification of hoses

-

Complete documentation of inspection and cleaning processes

-

Efficient hose management through unique identification

-

Time-saving thanks to automated RFID reading

-

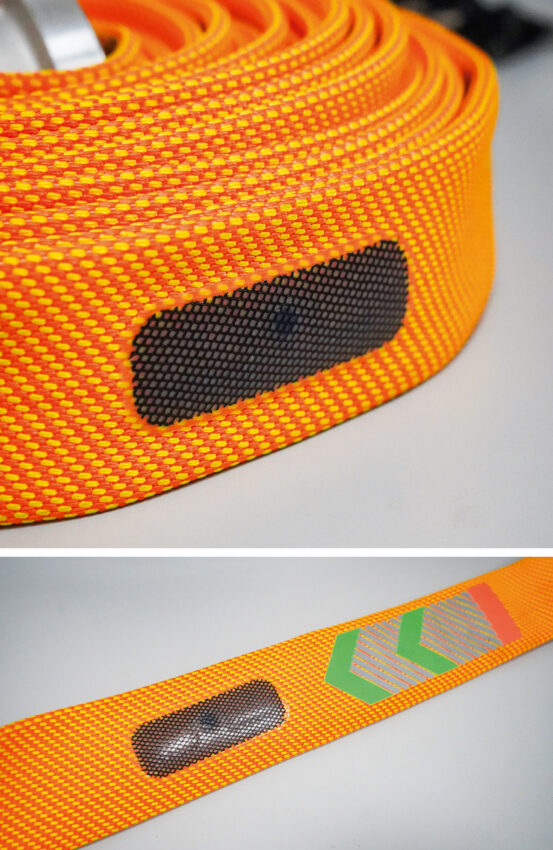

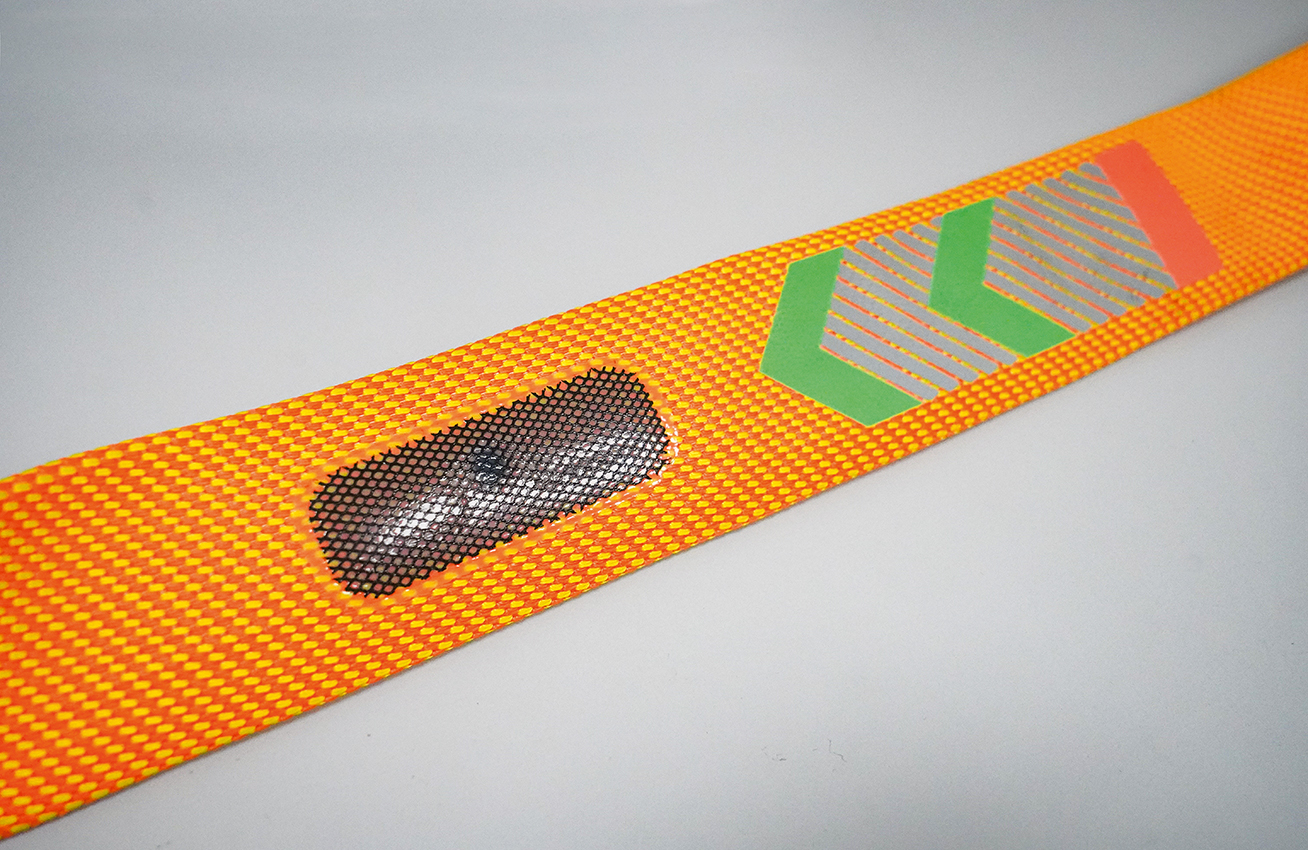

Strong hold on all hose types due to weldable multi-component film

Product Features

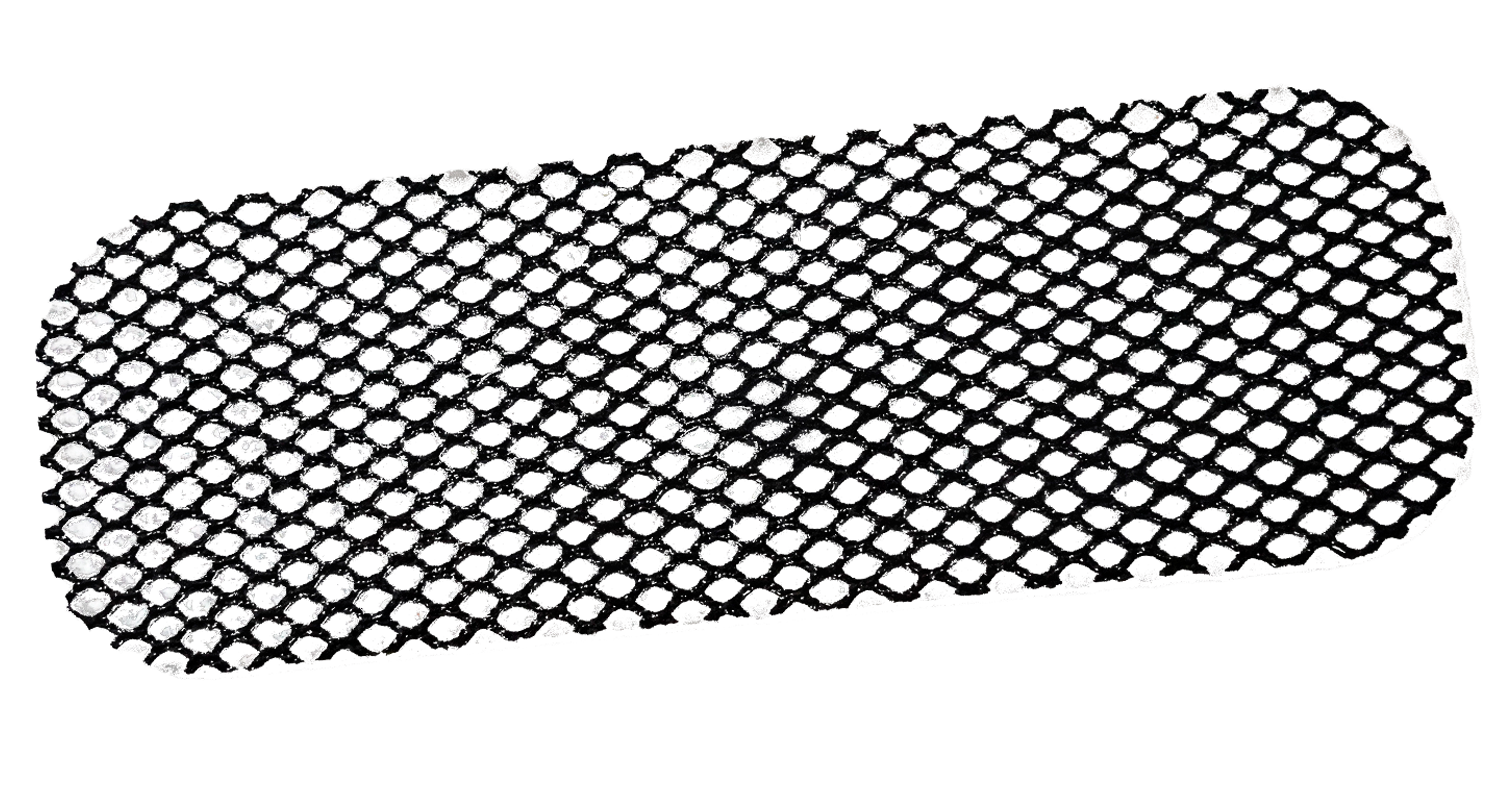

The OSW smartTAG is an RFID patch permanently applied to PU, rubber-coated or uncoated pressure hoses. It is made of a multi-component composite material with integrated transponder (128bit EPC memory). The patch is welded to the hose using a patch machine and adheres firmly. The ground surface with edge-glide effect ensures minimal friction during hose use.

With a size of 90 mm x 30 mm ±1 mm and a weight of 20 g, the smartTAG is compact and robust. Its thickness is 600 µm, with a density of 1.18 g/cm³. It withstands continuous pressure up to 26 bar and operates within a temperature range from – 40 °C to + 90 °C. The melting point lies between 100 – 135 °C (avoid temperatures above 200 °C). It is resistant to chemical cleaning agents and passed pressure tests at 40 bar with 20 cycles and abrasion tests according to DIN14811 with 200 cycles.

The transponder works at a frequency of 868 – 928 MHz ± 5 MHz in accordance with the RFID standard EPC C1 Gen. 2.2 / IEC/ISO 18000-6c and can be used globally.

RFID Technology

The abbreviation RFID stands for „Radio Frequency Identification“ and refers to the contactless transmission of data between a transponder and a reader. RFID technology enables the unique identification and management of equipment such as hoses. With the OSW smartTAG, all relevant information can be stored digitally – from the last cleaning cycle to the next inspection date. This gives you full control over your hose inventory and helps prevent manual errors.

Note on durability

When stored properly – in a dry, cool, ventilated, and light-protected environment – the OSW smartTAG guarantees a service life of at least four years. The patch should not be stored below 0 °C or above 40 °C. Avoid direct sunlight, heat sources, and aggressive chemicals. To prevent mechanical damage, we recommend storing the transponders in suitable containers. Improper storage can impair the functionality of the electronic components. Under optimal conditions, long-term and reliable use is ensured.

Video OSW smartTAG

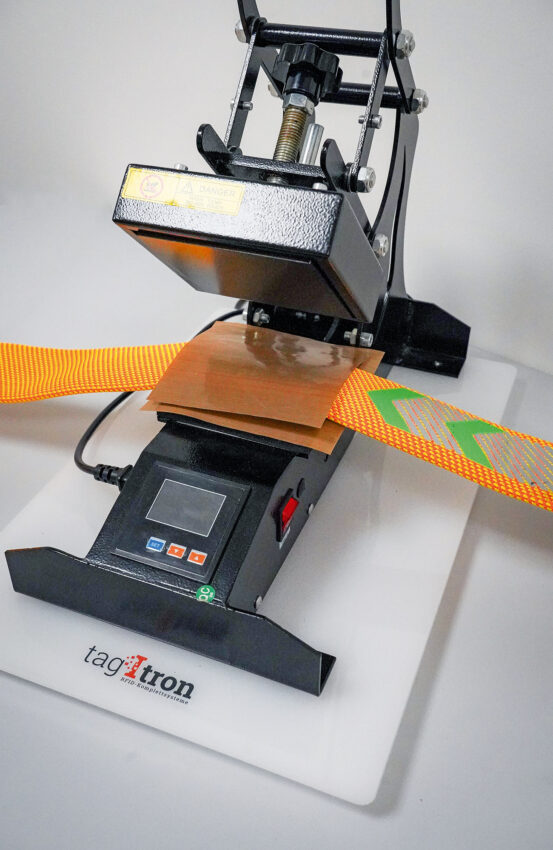

Installation OSW smartTAG

The patch is applied to the hose using a special welding process and a patching machine. Once attached, it cannot be removed, ensuring permanent marking. All RFID transponders of the „smartTAG“ passed tests for exposure to heat, pressure, and cleaning agents without any loss of function.

Production

Pictures, videos and descriptions from the production

Media

Galleries, videos and PDF

Glossary

Alphabetically arranged subject index, multilingual