Production of inside and outside rubber-lined hoses

Twisting (Cotton-spinning mill) inside and outside rubber-lined hoses

Every fabric consists of longitudinally taut threads, so called warp threads, through which another thread, called weft (thread), is lead across [the running direction of the warp threads.] Thereby the weft is woven under and over the warp threads. If you press the threads together you get a woven fabric. According to the requirements for the fabric, threads have to be of different strength and texture.

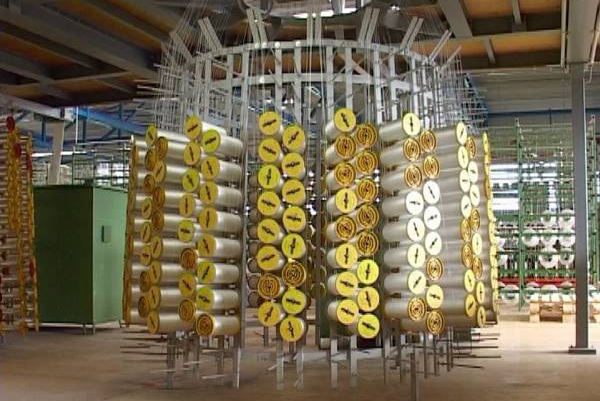

In order to reach highest flexibility and effectiveness the OSW Eschbach GmbH spins the warp threads and wefts needed in their own spinning mill. Hence there are no shortness of supplies or delays, even with special orders by the customers. The thread making machines are able to twist up to 12 threads of high-quality polyester yawn simultaneously at great speed to form a single warp thread or weft, depending on what strength is needed for weaving. As a rule of thumb, you can say that the rougher the use of the hose and the bigger the diameter will be, the stronger threads are needed.

Synthetic yawn has established as raw material in practice because of its excellent characteristics, like its tear strength/resistance and stability. An employee threads the single filaments through hundreds of eyelets in the right spot, to ensure there will be no knots and that access to each filament is granted anytime. The machine coils the twined threads onto the spools at constant speed. The large twining machines manage up to 1000 threads simultaneously and produce right up to 300.000 meters per hour. Afterwards another employee places the spools directly on the loom for immediate further process.