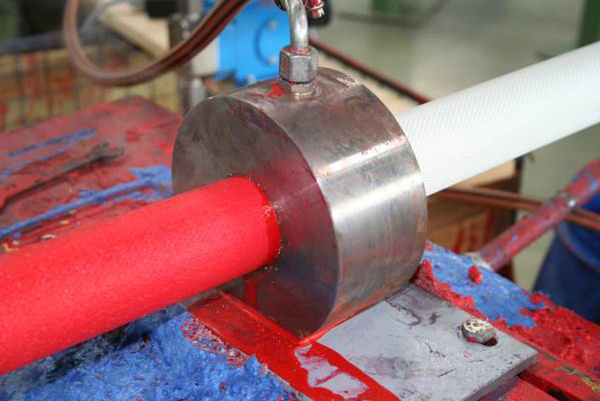

Production of the fire hose with internal rubber lining

Processing in the endless machine fire hose with internal rubber lining

Inside the endless machine the glue-coated manchon with its woven textile jacket gets vulcanized and receives an outer layer of color. Therefore, the hose [manchon which is pressed against the textile jacket with pressure from the inside] is lead through separated coloring-units twice, at a speed of 5m/min. After each coloring-unit the hose is lead through a hot-air canal at ca. 220℃ [428℉] in which the color layer can dry and the adhesive glue gets activated. The hose cools in the following water basin and gets finally coated with a foil.

A caterpillar drive causes the longitudinal movement in the machine which, like many hands, reaches for the hose and pulls it steadily forward. This production line is called endless machine, because the hoses are not yet cut to length after coloring and activating the adhesive glue, but coiled up on huge reels.

When the total length of the hose has been processed the cutting can start in the following steps. A special roll up device which is electronically controlled pulls the needed hose length (prior entered in the computer) from the storage reels and coils it up. An employee accompanies this process, cuts the individually measured hose with a knife, takes it off the machine and bundles it. This procedure proves itself especially in orders of nonmetric units like ft./feet, or to produce hoses with extreme lengths up to 200m.