Production of the fire hose with internal rubber lining

Weaving fire hose with internal rubber lining

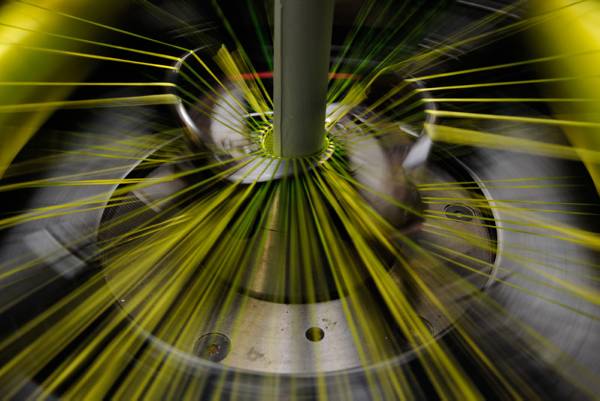

The woven fire hose characteristically consists of a thick textile jacket made of many thin threads, which is necessary to guarantee a high bursting pressure. On the top floor of the building there are the weaving looms that cover the manchon with the textile jacket.

During the weaving process warp threads and weft threads are automatically being checked for the correct tension and firmness. If a thread bursts or a spool gets empty, the machine stops immediately. In that case an employee puts in a new spool or connects the threads with an air-pressure machine, which is called splicing. Because of the splicing there will be no bulges in the hose, as knots would cause.

The weaving process at its operating speed is hardly comprehensible with the human eye. Only at a creeping speed you can see how the machine lifts and lowers the warp threads to insert the weft threads.

About 20 meters of manchon with a woven jacket can be made within one hour that way. The diameters of the textile hoses range from 19 mm to 200 mm.